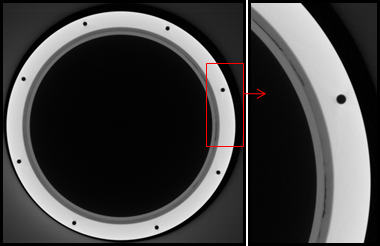

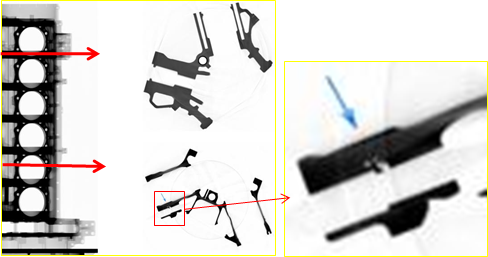

It can give a tomographic image of the tested object, reproduce the internal structure, density distribution, defect location, etc. of the object, and can accurately measure the internal structure and defect size of the tested object. In the manufacturing industry, it is mainly used for quantitative detection of internal defects of parts and complete machines and assembly correctness inspection, and can also be used in the field of reverse engineering. At present, such products have been widely used in many industries such as aerospace, aviation, railways, ships, electronics, and machinery.

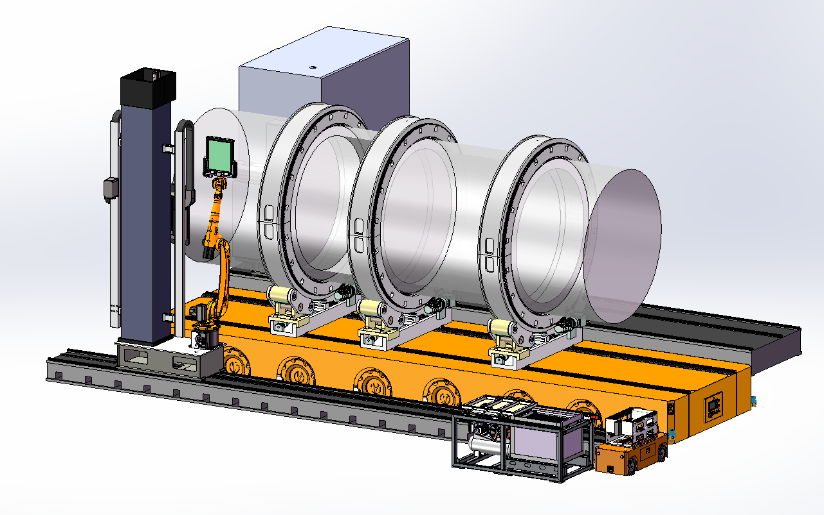

The high-energy industrial CT inspection system can be equipped with linear accelerators of different energies (2MeV, 4MeV, 6MeV, 9MeV, 15MeV), and optional area array detectors or linear array detectors, and can also use multi-ray sources and multi-detector combinations to meet Various testing needs. According to the detection method and mechanical structure, it can be divided into vertical system, horizontal system and vertical and horizontal dual purpose. At the same time, advanced X-band linear accelerators are used as ray sources, digital imaging detectors and high-precision mechanical detection platforms. It not only accurately reproduces the CT tomography and three-dimensional images of the inspected workpiece, but also has the function of two-dimensional real-time imaging. The product has many advantages such as high degree of customization, fast detection speed, clear image, accurate detection and strong penetration. Accelerator industrial CT technology is mainly used to detect workpieces with larger or extra-large geometric dimensions, higher density, and higher value.

|

Energy/MeV |

1-2 |

3-4 |

6 |

9 |

15 |

|

Resolution |

1.0~2.5LP/mm |

1.0~2.5LP/mm |

1.0~2.5LP/mm |

1.0~2.0LP/mm |

1.0~1.5LP/mm |

|

Spot size |

≤2 mm |

≤2 mm |

≤0.5-2 mm |

≤2 mm |

≤3 mm |

|

Dose rate/min@1m |

≥200

|

≥500

|

≥200-800

|

≥3000

|

≥20000

|

|

Equivalent steel penetration |

40~200mm

|

50~250mm

|

40~280mm

|

75~380mm

|

75~450mm

|

|

Density resolution |

0.3% (within the area of Φ20mm) |

||||

|

Scannng mode |

Vertical, horizontal or two-in-one (vertical and horizontal) |

||||